MET25-05-1.20

1.20μF 250v

h4>Mylar – Metallized Polyester Film Capacitors

ERSE’s PEx Film Capacitors are an excellent choice for a wide range of audio and electrical applications. Wound with premium Dupont mylar film to a 5% tolerance. ERSE’s PEx capacitors have fused high purity leads and is outer wrapped with polyester tape and then hermetically sealed for reliable long term performance. The PEx caps are perfect for crossover networks, coupling circuits, bypass circuits, or blocking of lower frequency systems. ERSE PEx caps have very small deviation in capacitance over a wide range of frequencies.

Description

Specifications

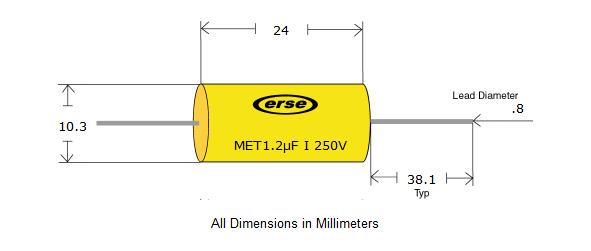

- Capacitance

- 1.2 µF

- Voltage Rating

- 250 VDC

- Tolerance

- 5.0%

- Dissipation Factor

- .0041

- Outside Diameter

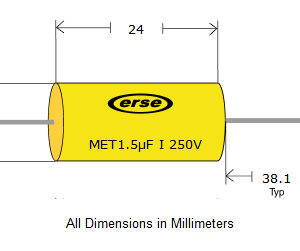

- 10.3 mm

- Length

- 24 mm

- Wire Diameter

- .8 mm

- Lead Length

- 38.1 mm

- RoHS Compliant

- No

- Weight

- .0054 lb